IN THIS ARTICLE

Are you looking for a price list for the production of clothing on behalf of third partiesYou have probably already discovered that finding clear, up-to-date information on this subject is more difficult than you thought.

Manufacturers rarely publish their prices online. When you contact them, the answers are vague: “it depends on the quantity,” “we need to see the model,” “send us the specifications.” And you're left there, with no idea how much you should budget for your collection.

I am Corrado Manenti, founder of Be A Designer. For over 14 years I work in the Italian fashion production chain., supporting emerging designers in the creation of their collections. During this time, I have built relationships with dozens of workshops, subcontractors and manufacturers throughout Italy, and I have a clear understanding of how prices really work in this sector.

In this article I'll give you the numbers you're looking for: realistic price ranges for each product category, an explanation of the factors that influence costs, and above all, an honest perspective on what you can expect when you approach the world of contract clothing manufacturing.

Please note: this article is not a price list from which you can copy figures for your business plan. The figures you will find are indicative and vary greatly depending on factors that we will explore in more detail. However, they will give you a rough idea of the order of magnitude you need to consider.

If you would like a comprehensive overview of all the costs involved in launching a brand (not just production), I recommend reading our main guide: “How much does it cost to create a fashion brand in 2026?“.

How contract clothing manufacturing works in Italy

Before discussing prices, it is essential to understand how the contract manufacturing system works – or “third party” – in the Italian fashion industry.

Contract clothing manufacturing means entrust the production of your garments to a specialised external company. You provide the design, technical specifications and (often) the materials; they take care of the cutting, sewing and finishing. In essence, they transform your idea into a finished product.

Italy has one of the richest and most specialised production chains in the world.. There are workshops for every type of manufacturing: knitwear, shirts, trousers, outerwear, leather goods, and so on. Many of these work for major luxury brands, but they also accept commissions from smaller brands.

Types of contract manufacturers

Not all subcontractors are the same. Here are the main categories:

Artisan workshops:

Small businesses, often family-run, with 2-10 employees. They offer flexibility and accept small quantities, but have limited production capacity and longer lead times. Ideal for prototypes and micro-production.

Semi-industrial subcontractors:

Medium-sized companies (10-50 employees) with more advanced machinery. Good compromise between flexibility and production capacity. MOQ typically 50-100 pieces per model.

Industrial manufacturers:

Large companies with structured production lines. More competitive prices for large volumes, but high MOQs (500-1000+ pieces) and little flexibility on customisation. Not suitable for emerging brands.

Full service/Private label:

Companies that offer a complete service, from design to production. Useful if you lack technical expertise, but with less creative control and higher costs.

The 7 factors that determine the production price

Before looking at the figures, you need to understand why prices vary so much. A T-shirt It may cost €8 or €25 depending on these factors:

1. Minimum Order Quantity (MOQ)

This is the most important factor. The unit price drops significantly as quantities increase. A sweatshirt produced in 30 pieces may cost €40; the same sweatshirt in 500 pieces may drop to €22. This is because fixed costs (machine setup, paper patterns, preparation time) are spread over more units.

2. Complexity of the model

More stitching, more time. A basic T-shirt requires few steps to make; a shirt with a collar, cuffs, buttons and pleats requires many more. Each additional step has a cost. Details such as zips, pockets, embroidery and appliqués increase the price.

3. Type of fabric

Fabrics that are difficult to work with cost more to manufacture. Silk, velvet, very light or very heavy fabrics require specific skills and more time. Some fabrics require special machinery.

4. Quality of finishes

Clean internal seams, invisible hems, high-quality buttons, woven labels instead of printed ones: everything has a cost. A brand that aims for accessible luxury will have higher manufacturing costs than a basic streetwear brand.

5. Laboratory location

Costs also vary geographically. Workshops in regions with a high concentration of fashion (Lombardy, Tuscany, Veneto, Emilia-Romagna) tend to have higher prices but also superior quality and reliability. Workshops in southern Italy may offer more competitive prices.

6. Urgency and timing

Are you in a hurry? You will pay more. Workshops have limited production capacity and plan their work in advance. If you request tight deadlines, they will have to reorganise production or work overtime. This comes at a cost.

7. Inclusion of materials

Some subcontractors only work on a “contract manufacturing” basis (you supply everything: fabrics, accessories, labels). Others offer a “full package” service where they source the materials themselves. In the latter case, the price is higher, but it also includes the mark-up on the materials.

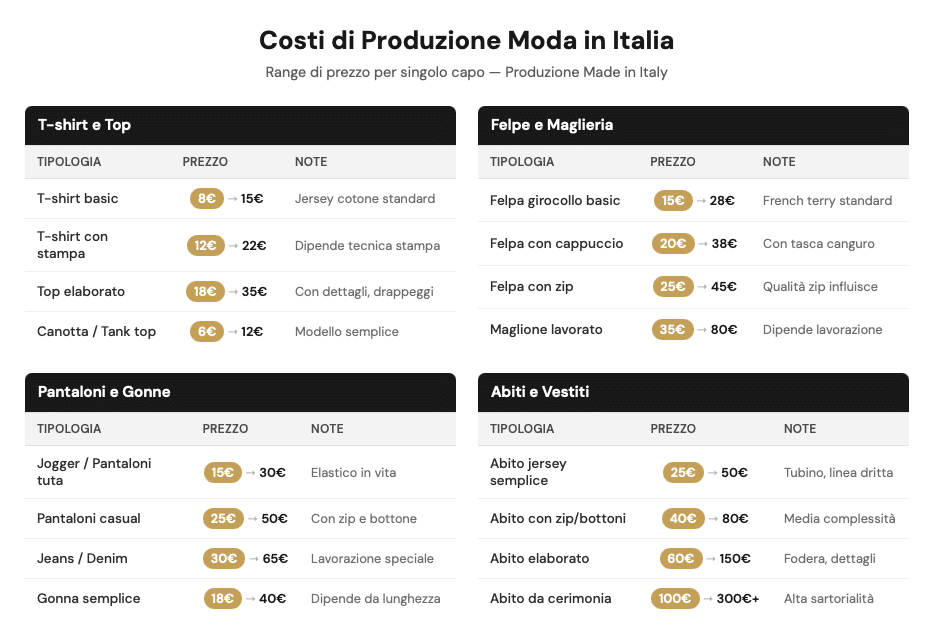

Clothing manufacturing for third parties prices by category

Here is The price ranges you can expect in 2026 for contract clothing manufacturing in Italy. These figures refer solely to packaging (labour), EXCLUDING materials, for typical quantities for an emerging brand (50-100 pieces per model).

IMPORTANT: These are indicative ranges based on our experience. Actual prices may vary significantly depending on the factors described above. Do not use them as a definitive reference for your business plan.

MOQ and delivery times: what to expect

Minimum Order Quantities (MOQ)

MOQs vary greatly depending on the type of manufacturer and the complexity of the garment:

- Artisan workshops: even 10-20 pieces per model (higher unit costs)

- Semi-industrial subcontractors: typically 30-100 pieces per model

- Industrial manufacturers: 300-1000+ pieces per model

- Knitwear: often higher MOQs (100-200 pieces) due to machine setups

Pro tip: Some workshops accept smaller orders if you have been working with them for some time or if the model is simple. Relationships are very important in this sector.

Typical Delivery Times

The times also vary greatly, but here are some realistic guidelines:

- Prototype/Sample: 2–4 weeks

- Small production (50-100 pieces): 4–8 weeks

- Average production (100-500 pieces): 6–12 weeks

- Outerwear/complex products: add 2–4 weeks

IMPORTANT: These times do NOT include the sourcing of materials. If you need to order specific fabrics, add another 4–8 weeks.

In my book “Do you also want to be a designer?“ I dedicate an entire chapter to fashion trends and how to plan production correctly. It is one of the most common mistakes: underestimating the time required and find yourself with the collection ready for the season already started.

How to find reliable manufacturers for small quantities

This is probably the question I am asked most often after the one about prices. And the answer is not simple.

Finding manufacturers who accept small quantities, offer acceptable quality, and don't charge absurd prices is one of the biggest challenges for those starting out. Most workshops have no interest in working with emerging brands: low margins, small orders, inexperienced customers who make a thousand changes.

Here are the paths you can take:

1. Independent Research

You can search for laboratories on Google, attend trade fairs, ask in forums. The problem? It takes months, you'll face many closed doors, and you risk running into unreliable suppliers. Without references, you're a stranger asking for small quantities – not exactly the ideal customer.

2. Easy Supply Chain

For those who want to speed up this phase, we have created Easy Chain: a database of over 130 verified Italian suppliers, organised by type of processing and willingness to work with small quantities. It costs less than £100 and saves you weeks of research.

3. Rely on professionals

The safest route – and the one I recommend if you want to do things properly – is to rely on those who have already built these relationships.

We of Be A Designer We have been working in the Italian supply chain for over 14 years. We have established relationships with dozens of manufacturers, we know who is reliable, who offers the best value for money for each type of product, and we can negotiate terms that a single emerging brand would never be able to obtain. Read more about how our system works. turnkey service.

The truth nobody tells you about production prices

Before closing, I want to be completely honest with you about some realities of the industry that are often overlooked.

Low prices come with a hidden cost.

If you find a workshop offering prices significantly lower than average, ask yourself why. Often it means: lower quality, unreliable turnaround times, poor finishes, or problems you will only discover when the garments arrive. I have seen too many brands waste time and money redoing faulty production runs from “cheap” suppliers.

The production cost is only part of the final price.

The prices you have seen in this article are for the garment alone. But to arrive at the total cost, you must add: fabrics, accessories (buttons, zips, labels), any prints or embroidery, packaging, and shipping. On average, the garment accounts for 30-40% of the total cost of an item.

Price does not make the brand.

If your competitive advantage is “low cost,” you've already lost. You cannot compete on price with those who manufacture in countries with low labour costs. The value of a Made in Italy brand lies in its uniqueness, quality, design, and storytelling – not in costing less.

As I often explain to my clients using the Fashion Business Designer Canvas™, the product is just one piece of the puzzle. You need to build a complete system: brand, communication, distribution, customer experience. This is what transforms clothing into a valuable brand. To better understand this approach, read our introduction to Brand Design.

DISCOVER HOW TO USE THE FASHION BUSINESS DESIGNER CANVAS

SUBSCRIBE TO THE NEWSLETTER AND DOWNLOAD FOR FREE:

Click on the button below

and follow the instructions:

Frequently Asked Questions

Can I produce in Italy on a very limited budget?

Yes, but with realistic expectations. With very low budgets, you can produce small quantities of simple products (T-shirts, basic sweatshirts). For more structured collections or complex products, adequate resources are needed. A common mistake is trying to do too much with too little, resulting in mediocre results. Better to have a capsule collection of a few well-made pieces than a large collection of poor quality.

Is it better to manufacture in Italy or abroad?

It depends on your positioning. For a brand that focuses on quality and Made in Italy, manufacturing abroad would be contradictory. Italian costs are higher, but you have: superior quality, direct control, rapid response times, and the ability to authentically communicate Made in Italy. For commodity products where price is everything, manufacturing abroad may make sense – but that's not the type of brand we help create.

How do I know if a price is fair?

Always compare at least three quotes for the same product. If one is significantly lower than the others, be wary. Also consider: what is included in the price? Does the laboratory have experience with that type of product? What are their references? Sometimes paying 20% more for a reliable supplier saves you a lot in the long run.

Do I need to provide the fabrics or will the workshop supply them?

Both options exist. If you supply the fabrics yourself (“processing account”), you have more control and potentially lower costs, but you have to manage your own purchases. If the workshop procures them (“full package”), it is simpler but you will pay a mark-up. For those just starting out, it is often better to start with a more comprehensive service and then, with experience, manage procurement directly.

How do I manage sizes? Do I have to produce all sizes in equal quantities?

No, and this is a common mistake. Size distribution follows a curve: medium sizes (M, L) sell more than extreme sizes (XS, XXL). A typical distribution for the UK might be: S 15%, M 30%, L 30%, XL 20%, XXL 5%. But it depends a lot on your specific target audience. Start with a focused collection and adjust the distribution based on actual sales data.

How much does a prototype/sample cost?

The cost of a prototype is generally higher than the unit production cost (even 2-3 times higher) because it includes pattern development and setup. For a simple T-shirt, you can spend £80-150 on the prototype; for a structured coat, even £400-600. Some workshops will refund part of the prototype cost if you then proceed with production.

Conclusion: the numbers are just the beginning

Now you have a clearer idea of production prices in the Italian fashion industry. But remember: these figures are only a starting point for your planning, not an absolute truth.

Production is a fundamental part of your brand, but it is not everything. As I write in my book “Il Viaggio dello Stilista” (The Designer's Journey), creating products is only part of the fashion business. The real challenge is transforming those products into a brand that people desire, purchase, and recommend.

If you want a comprehensive overview of all the costs involved in launching a brand – not just production – I recommend reading our main guide: “How much does it cost to create a fashion brand in 2026?“.

And if you have specific questions about your project, book a free consultation. We will analyse your idea together and I will give you concrete information about the costs and the steps to follow.

Good luck with your project!

Corrado Manenti

Founder of Be A Designer